As a result, the preparatory-final transition time is significantly reduced and the processing accuracy is increased.

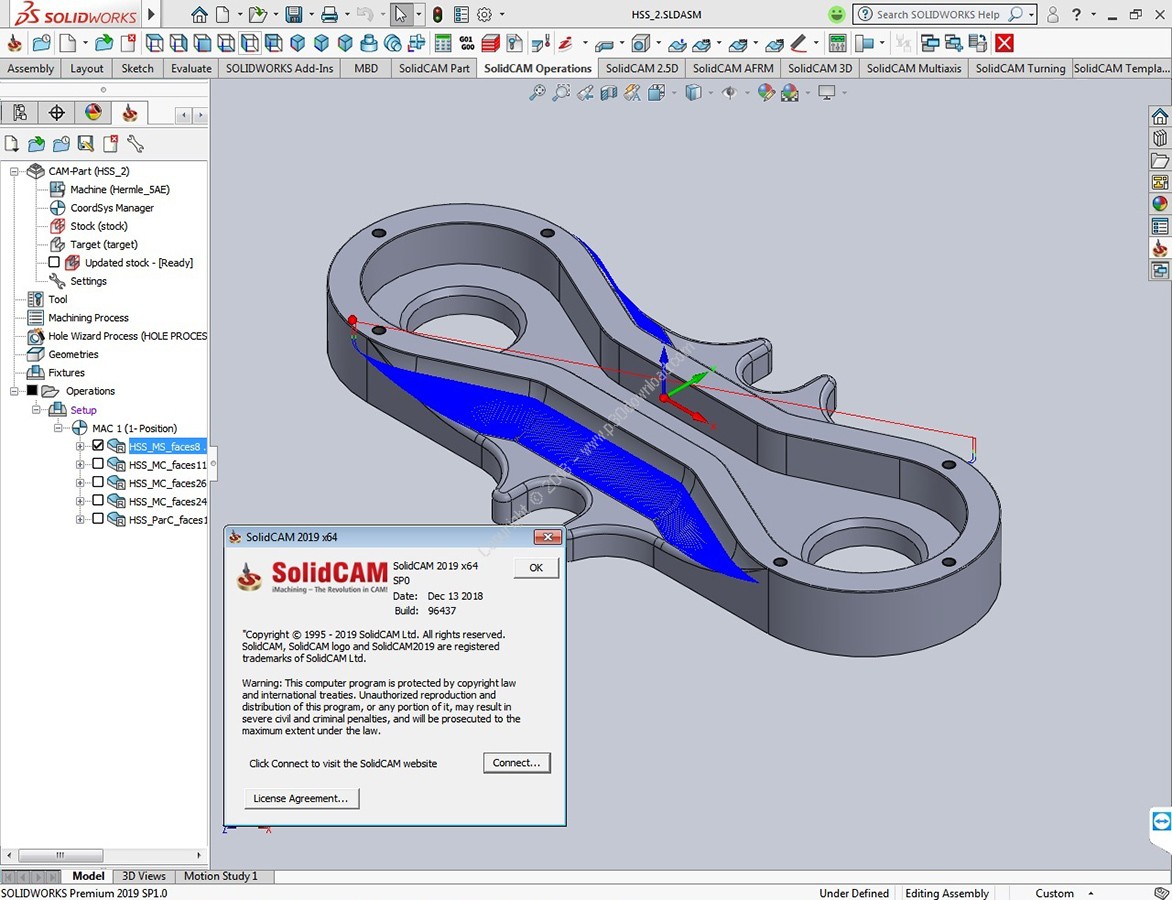

The model is installed in a user-defined processing plane, after which the system automatically calculates all the necessary offset and rotation parameters for the part zero. SolidCAM offers various tools for creating multi-axis machining control programs at 4- and 5-axis machining centers. The absence of killing is guaranteed by the availability of means of control and visualization of machining. Once created, such a parameterized technological process can be used repeatedly in the future, which significantly reduces the time for production preparation, increases the reliability of the developed programs, unifies the style of technological developments, guarantees the use of only optimal processing technologies and ensures the independence of production from the human factor. It is possible to create a database of typical technological processes.

In addition to the already mentioned features of 2.5- and 3-coordinate processing, SolidCAM offers tools for identifying and finalizing sections that were not processed in previous transitions. The system supports various types of roughing and finishing strategies, such as raster processing with a given or automatically determined raster angle, equidistant processing, projection processing, waterline processing, etc. As geometry for 3-axis machining, a three-dimensional surface or solid model is used.

SolidCAM provides a wide range of tools that can be effectively used for processing products with complex geometry (dies, molds) and prismatic parts. The system has a wide range of capabilities for 2.5-coordinate processing of analytical surfaces. Various processing strategies are supported for elements such as contour, sampling (with islands) and a groove, as well as various types of hole processing: drilling, countersinking, threading, etc. SolidCAM provides high efficiency and precision 2.5-axis milling of parts.

Support for 64bit computing due to the availability of a special version for SW 64bit Using a wide range of SolidCAM proposed strategies for turning, milling, turning, milling and EDM, the technologist can quickly prepare the necessary set of control programs for machining the product. This system is a complete solution for the automation of metalworking production. Programming with SolidCAM 2019 SP2 HF4 for SolidWorks 2012-2020 fullĭescription:SolidCAM is a new generation CAD / CAM system developed by the Israeli company SolidCAM Ltd (Official distributor in Russia – Consistent Software). Download SolidCAM 2019 SP2 HF4 for SolidWorks 2012-2020 圆4 full Link download SolidCAM 2019 SP2 HF4 Multilang for SolidWorks 2012-2020 win64

0 kommentar(er)

0 kommentar(er)